Welding

111 MMA

We use this welding method for metal structures, industrial pipelines, and oil tank installations. With the 111 method, we weld all possible steel types from groups FM1, FM2, FM3, FM4, and FM5. We have extensive experience in 111 welding, including welding pipes of various diameters. The wall thickness starts from 2 mm. We also offer electrode welding services for 2 mm thick stainless steel pipes.

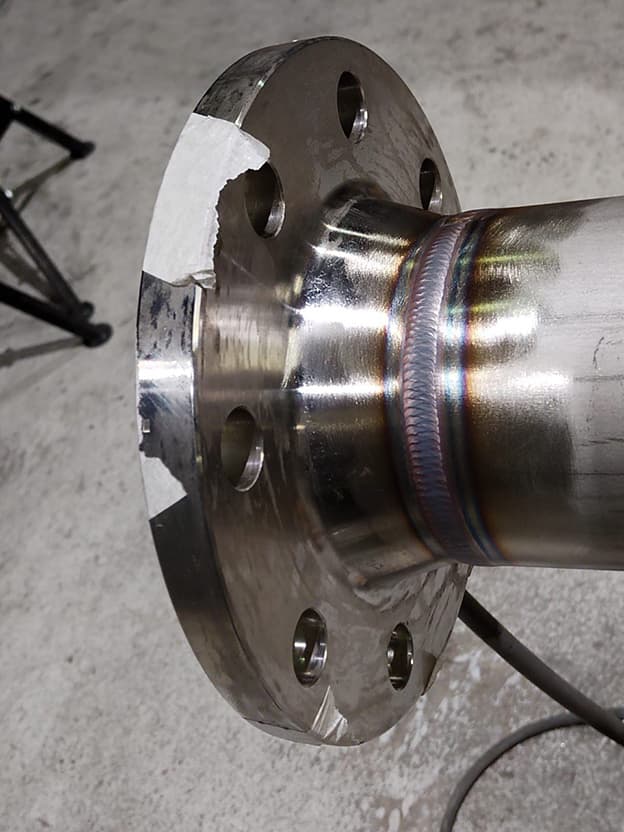

141 TIG

This welding method is in high demand today, and we have achieved an excellent level of expertise in the 141 method. We use it for welding various pipes with wall thicknesses starting from 1.5 mm. We specialize in welding all possible steel types, including FM1, FM2, FM3, FM4, and FM5 groups. Additionally, we have experience in welding special steels such as Duplex, Superduplex, Inconel, and X10Cr13.

In tight spaces, such as inside a boiler or in a corner pipe joint with limited visibility, our welders use mirrors to perform high-quality welding.

135/136 MIG/MAG

For welding pipes and metal structures in workshops, as well as for welding oil tanks, we use the 135/136 processes depending on the structure’s requirements. Typically, we weld FM1, FM2, and FM5 steels with the 135/136 method. This welding method enables the fast and efficient production of steel structures and large-diameter pipes indoors. We also use 135/136 for efficiently welding long seams of oil tanks spanning multiple kilometers.